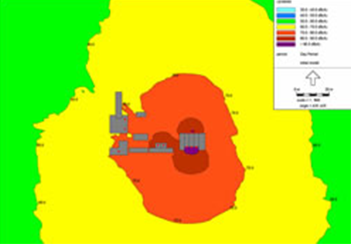

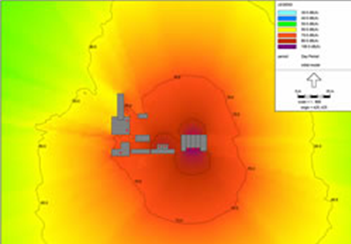

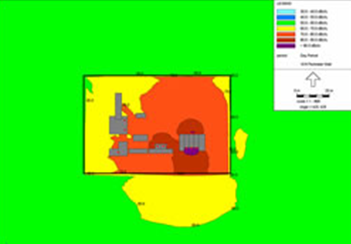

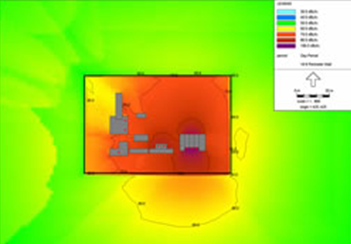

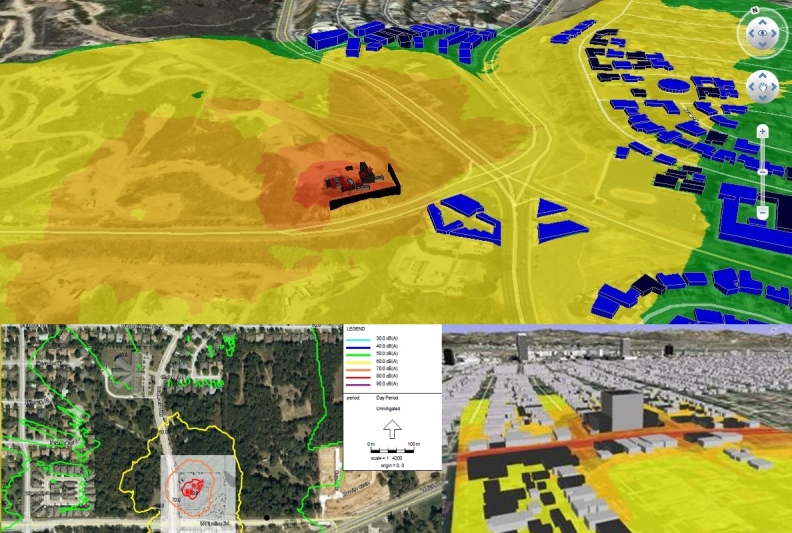

Complying with noise ordinances when drilling close to urban development can waste valuable time & money. Environmental Noise Control, Inc. uses state-of-the-art computer noise impact modeling software to help its clients make informed decisions about noise control issues. ENC can create an environmental noise impact model of specific drilling rigs and predict operational drilling noise levels at nearby houses, parks, businesses, or other noise-sensitive areas. ENC can evaluate noise mitigation options with the noise impact model to determine the most cost-effective solution to various drilling-related noise problems.

ENC drilling rig noise impact models are based on operational field drilling rig noise levels measured by ENC personnel. Over the years, ENC has measured & compiled operational drilling rig noise level data from many rig fleets, including Patterson, H&P, Ensign, Felderhoff, Patman, Pioneer, Nomac, Nabors, Grey Wolf, Goober, Cheyenne, Aquila, Unit, Bronco, and others. Using sound-level data from specific drilling rigs, ENC can make more accurate noise impact models and recommend rig layout and equipment positioning.

Contact Environmental Noise Control about its drilling rig sound prediction, noise impact modeling, or noise mitigation evaluation services.