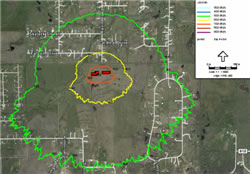

Oil & gas production and transmission operations in urban areas have become more challenging with increasingly strict local, state, and federal oil and gas-related noise ordinances. Many noise ordinances contain in-depth matrices specifying maximum allowable noise levels measured at specific distances from noise-generating equipment such as drilling rigs, compressors, and fracturing equipment. Without an understanding of the potential noise impact of the planned drilling rig, compressor, or fracing equipment, operators can lose valuable time & money dealing with oil and gas-related noise problems on urban drilling and compressor sites.

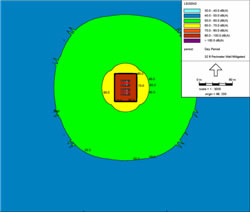

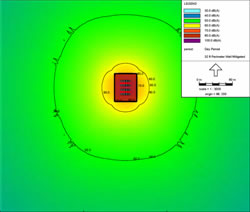

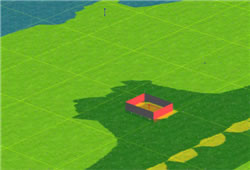

Environmental Noise Control, Inc. can then use the environmental noise impact model to evaluate potential noise mitigation solutions for oil & gas production and transmission operations that are out of compliance with noise ordinances or have other noise-related issues and concerns. ENC can input different combinations of acoustical barrier walls, acoustical buildings, and other mitigation into the model to create a series of mitigated noise impact models. The predicted noise levels from the unmitigated and mitigated environmental noise impact models are compiled into a report and supplied to its client. With the noise impact model report, ENC’s clients can see an assortment of projected noise mitigation results and implementation costs before any noisy equipment is ever operated on-site.

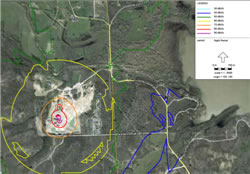

ENC constructs its noise impact models with the latest version of Predictor Type 7810 software developed by Brűel & Kjær, a recognized leader in the field of acoustics & vibration. Predictor Type 7810 software calculates the noise impact model while considering the noise attenuation effects of environmental variables such as atmospheric conditions, ground cover, and surrounding site topography. The calculation method used by the software complies with ISO 9613 standards.

Contact Environmental Noise Control about its oil & gas operational sound prediction & noise mitigation evaluation services.